Incident Energy Analysis

Having a Blast with Arc Flash!

Arc Flash Events contribute to over 600 workplace injuries on average each year. To ensure your workforce is adequately protected, it is essential to understand the level of arc flash hazards in your facilities and incident energy for specific pieces of equipment.

Service Details

Electrical workers must be able to wear arc-rated PPE that adequately protects them from the hazards to which they may be exposed. To know what levels of PPE to wear, they must know how much incident energy is available on the components that they might be performing working on. The best method to identify these values and protect your workers is to conduct Arc Flash Evaluations in your facilities. ElecTrain’s arc flash experts utilize the guidance of IEEE 1584 and the software packages from SKM Power Tools to perform a detailed inspection of your plant or facility.

- Incident Energy is unique for each electrical component. Each calculation must take into account many factors, some of which are: upstream transformer impedance, conductor length and size, over-current protection device settings, and electrode orientation.

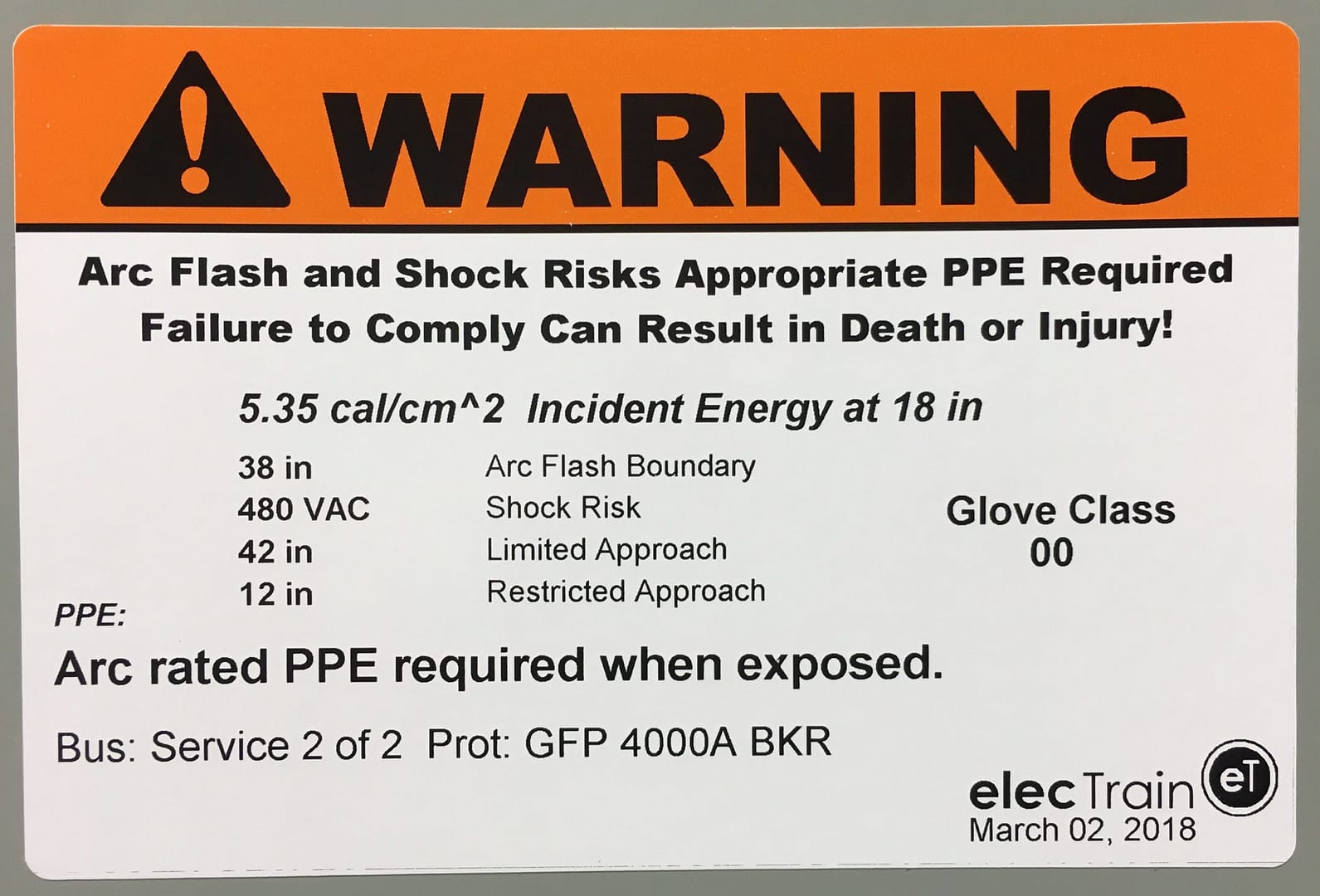

- A completed evaluation will provide the calculated Incident Energy, Working Distance, and Arc Flash Boundary for all electrical components capable of sustaining and arc flash.

- ElecTrain’s Equipment Incident Energy Labels comply with the labeling requirements of ANSI Z10 and contain all required information in compliance with NFPA 70E, Standard for Electrical Safety in the Workplace.

- These labels can also be customized to include additional information such as Restricted Approach Boundary, Limited Approach Boundary, class of voltage rated PPE required, etc.

- NFPA 70E requires that incident energy analysis shall be reviewed for accuracy at intervals not to exceed 5 years.

- Additionally, when new equipment is installed or existing equipment is modified or replaced with something NOT “like in kind”, a new incident energy analysis should be performed for that equipment and additional equipment affected by the system changes.

ONSITE AND REMOTE CONSULTATION

Applying excessive safety requirements can be just as hazardous as misinterpreting requirements from the standards. If your organization lacks the expertise to navigate the electrical safety requirements and practices, let us help keep you on track and keep your workers safe.

LEARN MORE

SAFETY PROGRAM AUDITS

When audits are performed by in-house personnel, often little time is allocated to perform the audit adequately and there can be hesitance to identify issues or raise concerns. This function is best performed by a third party to alleviate the extra responsibility of conducting the audits and ensuring that potential safety issues are properly identified and documented.

LEARN MORE

INCIDENT INVESTIGATION

Conducting a rushed and inadequate incident investigation only compounds the tragedy and leaves the door open for similar events to occur again. Ensure your workforce is protected from incident reoccurrence by using the right people for the right job and bring in our expertise to help navigate the way to resolve the programmatic issues.

LEARN MORE